Surface treatment to reduce hydrogen diffusion in steel tanks

Salzgitter Mannesmann Forschung GmbH and the Fraunhofer IST are developing surface treatments as protection against hydrogen embrittlement in ultra-high-strength Type I tanks. The barrier layer is intended to prevent the absorption of hydrogen into the steel material.

Motivation and definition of objectives

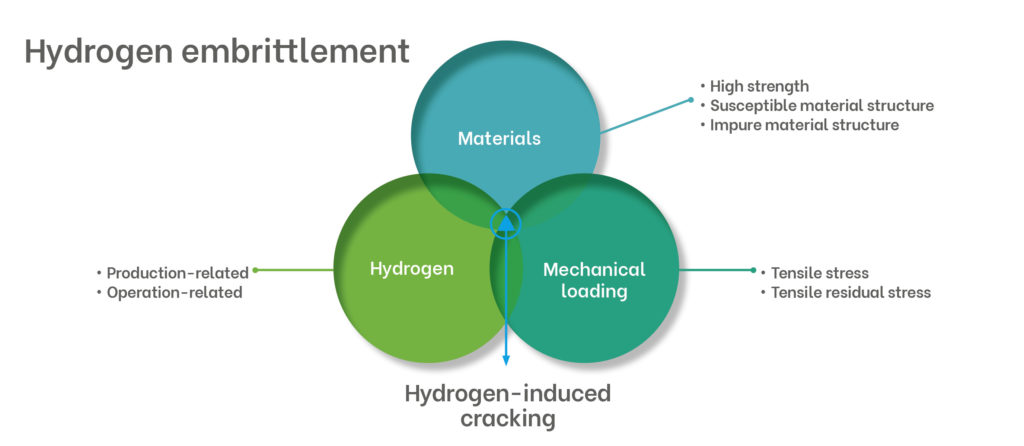

Despite very good recyclability, low material prices and economical manufacturing processes, the utilization of steel tanks is currently limited. The reasons for this are the high inherent weights and the tendency of ultra-high-strength steel grades towards hydrogen embrittlement.

The research objective of the project is therefore the development of a hydrogen barrier for tanks made from ultra-high-strength steel tubes. The utilization of these materials enables a reduction in the wall thickness and consequently offers the potential to reduce weight, costs and CO2 emissions.

Approach

The Fraunhofer IST is identifying, testing and evaluating potential surface treatments for preventing hydrogen embrittlement. These encompass both surface coatings and modifications which act as a barrier, thereby reducing hydrogen uptake and diffusion.

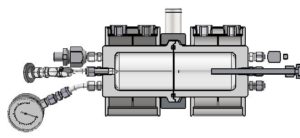

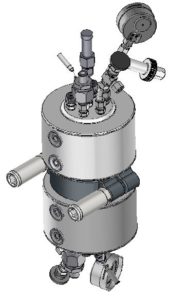

Salzgitter Mannesmann Forschung is developing a testing device for measuring hydrogen permeation and is verifying the effectiveness of the coating as a hydrogen barrier.

Literature research

Potential surface treatments:

- Galvanic Zi-Ni coatings exhibit low hydrogen diffusion

- Oxide and nitride modifications of Al, Ti and Cr show permeation values which are lower by two orders of magnitude

The following coating properties have a strong influence on permeation:

- Carbide-to-metal ratio

- Structure of the layer (roughness, morphology, grain size)

- Layer thickness

Hydrogen permeation

In the pressure chamber, the gaseous hydrogen is pressed against the disk-shaped material sample at up to 200 bar. On the opposite side is the measuring cell, which detects the escaping hydrogen. In addition, the sample can be elastically loaded, as this can have an influence on the hydrogen absorption. In this way, the penetration of hydrogen from the gas phase can be determined in a steel sample under conditions such as those in a high-pressure tank. The first step is to set up the test apparatus and establish the methodology. The measurement of coated samples makes it possible to determine the barrier effect.

Contact

Each partner of the consortium acts in its own name until the Wasserstoff Campus Salzgitter e.V. has been founded.

Wasserstoff Campus Salzgitter

on the premises of Robert Bosch Elektronik GmbH

John-F.-Kennedy-Str. 43 – 53

38228 Salzgitter

Allianz für die Region GmbH

Frankfurter Straße 284

38122 Braunschweig

Phone +49 531 1218-0

Contact

Fraunhofer-Institut für Schicht- und Oberflächentechnik IST

Bienroder Weg 54 E

38108 Braunschweig

Phone +49 531 2155-0

Contact

Salzgitter AG

Eisenhüttenstraße 99

38239 Salzgitter

Phone +49 5341 21-01

Contact

Alstom Transport Deutschland GmbH

Linke-Hofmann-Busch-Straße 1

38239 Salzgitter

Phone +49 5341 9000

Contact

MAN Energy Solutions SE

Stadtbachstraße 1

86153 Augsburg

Telefon +49 821 322-0

Contact

Stadt Salzgitter

Joachim-Campe-Straße 6 – 8

38226 Salzgitter

Phone +49 5341 839-0

Contact

Amt für regionale Landesentwicklung

Friedrich-Wilhelm-Straße 3

38100 Braunschweig

Phone +49 531 484-1002

Contact

Robert Bosch Elektronik GmbH

John-F.-Kennedy-Straße 43

38228 Salzgitter

Phone +49 531 2850

Contact

WEVG Salzgitter GmbH & Co. KG

Albert-Schweitzer-Straße 7-11

38226 Salzgitter

Phone +49 5341 408-216/-269

Contact